STUDTEK

- Overview

- Availability

- Gallery

- Downloads

- Support

Overview

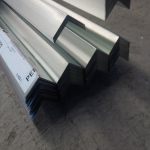

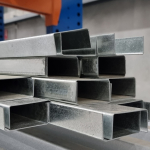

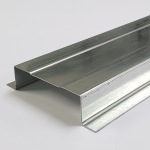

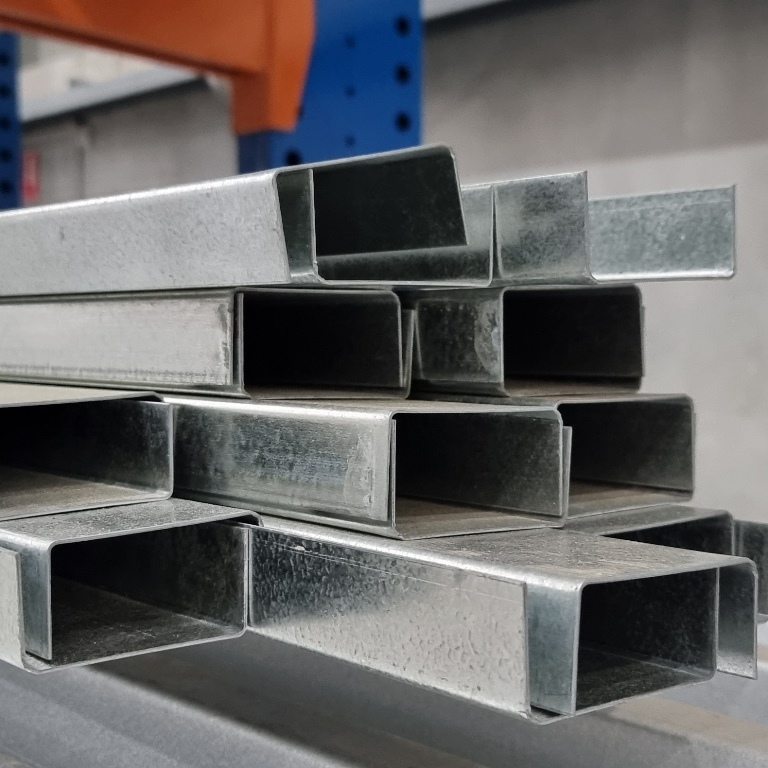

Steel Top-hat Framing System

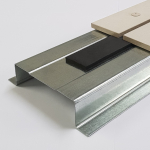

STUDTEK is a complete range of roll-formed steel sub-frame profiles designed for use with all types of cladding products. Including all different sizes of common profiles such as top-hats, c-channels and angles, STUDTEK also provides a highly versatile ventilated facade system which is widely used for installing many different cladding panels such as through-colour fibre cement, high-pressure laminate and 9mm CFC. Supplied with all the required accessories such as backing strips, cavity closers and foam gaskets for weatherproofing, the STUDTEK facade system is manufactured from zinc-coated steel in accordance with ISO 9001 for long-term durability.

Non-combustible

Made of 100% steel, STUDTEK steel cladding framing is deemed-to-satisfy non-combustible in accordance with NCC 2022, Clause C2D10(5)(b). STUDTEK foam gaskets and packers also comply with Clauses C2D10(4)(a) & C2D10(4)(i)(i).

Zinc Durability

Manufactured from high-grade zinc-coated steel, the STUDTEK facade system offers superior corrosion resistance and durability compared to common galvanised steel especially in coastal and marine environments.

ISO 9001 Assurance

Roll-formed using the latest state-of-the-art computer controlled (CNC) machines in accordance with ISO 9001, you can be assured that all STUDTEK steel cladding framing conforms with exacting dimensional tolerances and specifications.

Improved Strength

Not content with the common industry standard of 1.15BMT base-metal-thickness, key profiles in the STUDTEK range are made from stronger 1.20BMT steel to exceed normal engineering expectations and guarantee structural performance.

Back-to-Back Warranty

When you specify STUDTEK steel cladding framing with one of our many cladding products, we can offer additional peace-of-mind by providing a back-to-back warranty covering the complete system all from one supplier.

The Complete System

Along with the STUDTEK steel cladding framing and associated accessories such as backing strips, foam gaskets and cavity closers, we can also supply; BICEP facade brackets, IROCK insulation and ULTRAPERM membrane for the complete system.

All Cladding Types

As one of Australia's largest cladding suppliers, we are in the ideal position to design and supply compatible sub-frame systems. From high-spec architectural facades to common commodity cladding, STUDTEK has all bases covered.

Excellent Value

Superior zinc-coated finish and increased material base-metal-thickness (BMT) along with a manufacturer to industry direct supply chain means the STUDTEK facade system offers exceptional value-for-money to building owners.

Availability

Studtek Facade System

| SZ1203558 Joint Top-hat |

SZ503558 Intermediate Top-hat |

SCC60 Cavity Closer |

SJS*** Backing Strip |

|

|

|

|

|

Code |

Description |

Lead Time |

MOQ |

|---|---|---|---|

| SZ1203558 | STUDTEK 120 x 35mm Zinc-coated Joint Top-hat, 5.8m (1.20bmt) | Stock | 1 Length |

| SZ503558 | STUDTEK 50 x 35mm Zinc-coated Top-hat, 5.8m Length (1.20bmt) | Stock | 1 Length |

| SZA757560 | STUDTEK 75 x 75mm Zinc-coated Angle, 6.0m Length (1.15bmt) | Stock | 1 Length |

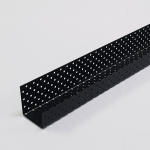

| SCC60 | STUDTEK 35 x 35mm Black Cavity Closer, 6.0m Length (0.55bmt) | Stock | 1 Length |

| SJS359 | STUDTEK 67 x 3.5mm Black Backing Strip, 3.59m Length (0.48bmt) | Stock | 1 Length |

| SJS299 | STUDTEK 67 x 3.5mm Black Backing Strip, 2.99m Length (0.48bmt) | Stock | 1 Length |

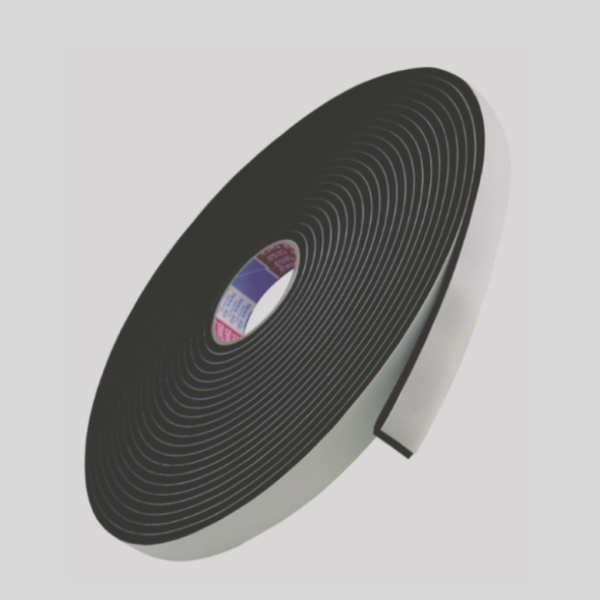

Studtek Adhesive Foam Gaskets

| TFG4048/32 Vertical Joint Gaskets |

JOINT GASKET Applied to Top-hat |

TFG1232 Intermediate Gasket |

|

|

|

|

Code |

Description |

Lead Time |

MOQ |

|---|---|---|---|

| TFG4048 | STUDTEK 40 x 4.8mm EPDM Vertical Joint Gasket, 15m Roll* | Stock | 1 Roll |

| TFG4032 | STUDTEK 40 x 3.2mm EPDM Vertical Joint Gasket, 25m Roll** | Stock | 1 Roll |

| TFG1232 | STUDTEK 12 x 3.2mm EPDM Intermediate Gasket, 25m Roll*** | Stock | 1 Roll |

*TFG4048: The 4.8mm thick vertical joint gasket is used on joint top-hats as shown in the image above for products which require 3-way panel movement such as Equitone. **TFG4032: The 3.2mm thick vertical joint gasket is used on joint top-hats as shown in the image above for products which are fixed hard against the top-hat such as 9mm Compressed CFC. ***TFG1232: The intermediate gasket is only applied to the intermediate top-hats when using the 4.8mm thick joint gasket for products which require 3-way panel movement.

Studtek Standard Cladding Sub-framing

| SZ1203558 Joint Top-hat |

SZ50**58 Standard Top-hat |

SZ653058 C-channel Framing |

|

|

|

| Code |

Description |

Lead Time |

MOQ |

|---|---|---|---|

| SZ1203558 | STUDTEK 120 x 35mm Zinc-coated Joint Top-hat, 5.8m (1.20bmt) | Stock | 1 Length |

| SZ505058 | STUDTEK 50 x 50mm Zinc-coated Top-hat, 5.8m Length (1.20bmt) | Stock | 1 Length |

| SZ503558 | STUDTEK 50 x 35mm Zinc-coated Top-hat, 5.8m Length (1.20bmt) | Stock | 1 Length |

| SZ502458 | STUDTEK 50 x 24mm Zinc-coated Top-hat, 5.8m Length (1.20bmt) | Stock | 1 Length |

| SZ501558 | STUDTEK 50 x 15mm Zinc-coated Top-hat, 5.8m Length (1.20bmt) | Stock | 1 Length |

| SZ653058 | STUDTEK 65 x 30mm Zinc-coated C-channel, 5.8m Length (1.20bmt) | Stock | 1 Length |

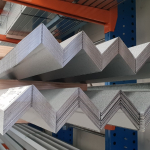

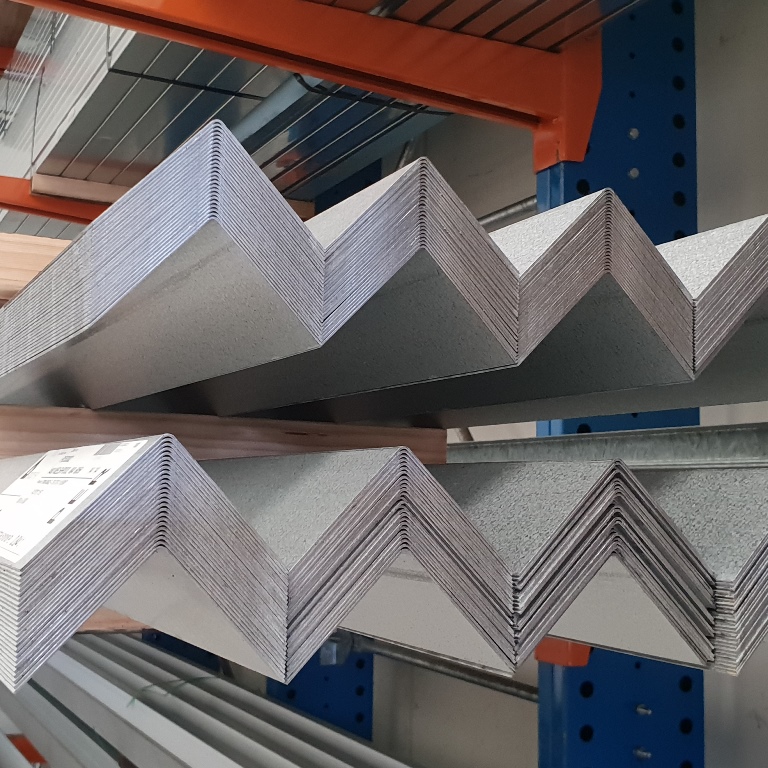

Studtek Angles & Horseshoe Packers

| SZA/SGA****** Angles |

BP*** Horseshoe Packers |

|

|

| Code |

Description |

Lead Time |

MOQ |

|---|---|---|---|

| SZA757560 | STUDTEK 75 x 75mm Zinc-coated Angle, 6.0m Length (1.15bmt) | Stock | 1 Length |

| SGA505036 | STUDTEK 50 x 50mm Angle, 3.6m Length (0.75bmt) | Stock | 1 Length |

| SGA353536 | STUDTEK 35 x 35mm Angle, 3.6m Length (0.75bmt) | Stock | 1 Length |

| SGA252536 | STUDTEK 25 x 25mm Angle, 3.6m Length (0.75bmt) | Stock | 1 Length |

| BP10 | STUDTEK 75 x 1.0mm Horseshoe Packers (White), 4000 Pack | Stock | 1 Pack |

| BP30 | STUDTEK 75 x 3.0mm Horseshoe Packers (Blue), 2000 Pack | Stock | 1 Pack |

| BP50 | STUDTEK 75 x 5.0mm Horseshoe Packers (Yellow), 1600 Pack | Stock | 1 Pack |

| BP100 | STUDTEK 75 x 10.0mm Horseshoe Packers (Black), 600 Pack | Stock | 1 Pack |

Gallery

Downloads

Support

Customer Support

For same-day design assistance and technical support please contact our sales team directly on the below contact details. All our sales team and technical staff are locally based here in each timezone of Australia (AU) so we can provide the best possible service and support for your projects.

You can also request pricing or project-specific quotations using the below contact details. Please note, each of our email addresses is as per the following format and as set out below:

| Ben Kennard | Daniel Hornsey | James Alexander | Jon Wallis |

| NSW & ACT | VIC & TAS | WA & SA | QLD & NT |

| P: 1300 945 123 | P: 1300 945 123 | P: 1300 945 123 | P: 1300 945 123 |

| M: 0400 888 333 | M: 0429 936 164 | M: 0477 966 028 | M: 0437 606 007 |

| Email Handle: ben.k@ | Email Handle: daniel@ | Email Handle: james@ | Email Handle: jon@ |

| LinkedIn Profile | LinkedIn Profile | LinkedIn Profile | LinkedIn Profile |

- Overview

- Availability

- Gallery

- Downloads

- Support