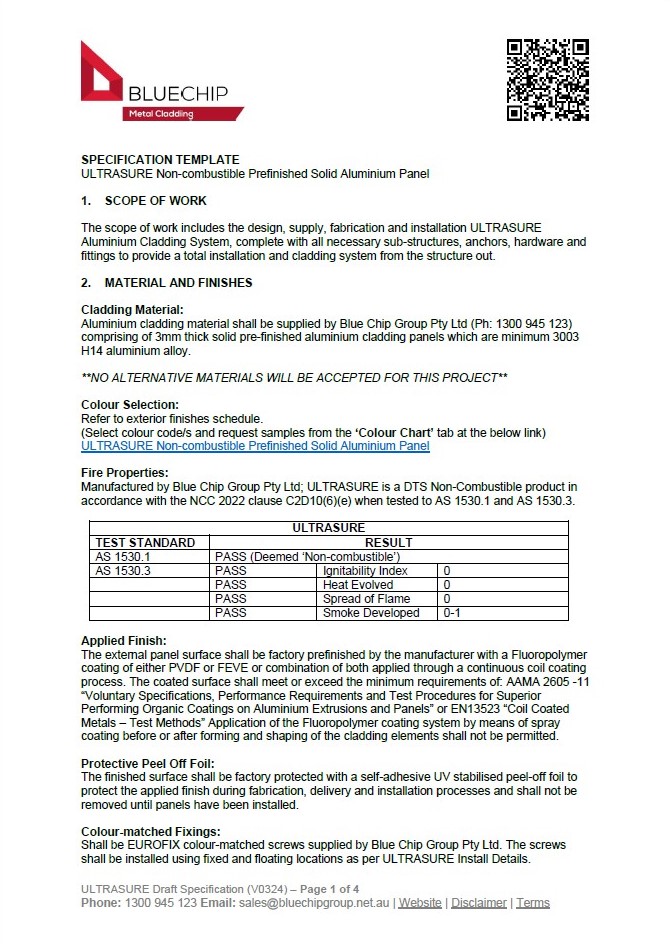

ULTRASURE

- Overview

- Availability

- Colour Chart

- Gallery

- Downloads

- Support

Overview

Prefinished Solid Aluminium Panel

ULTRASURE completes our range of NCC compliant, deemed-to-satisfy non-combustible aluminium cladding solutions. Offering very high impact resistance and the ability to be curved, rolled or perforated, ULTRASURE panels do not require fabrication prior to coating, greatly reducing lead-times and costs. Due to its high thermal movement and the risk of score fracturing, ULTRASURE, like all 3mm solid aluminium panels, is NOT suitable for use in the common v-groove cassette fixing method, however it can be face-fixed or break-pressed into the traditional rainscreen hook-and-rail cassette system*. For the common v-groove cassette fixing method use ULTRACORE IQ intelligent non-combustible core panel.

*Face-fix or Break-press Only

BLUECHIP does NOT endorse installing any brand of SOLID aluminium panels with the v-grooved cassette system - it is a fundamentally flawed methodology which will lead to future structural failure and water ingress issues. For the common v-groove cassette fixing method use ULTRACORE IQ intelligent non-combustible core panel.

Curve, Roll or Perforate

The ULTRASURE 3mm aluminium panel offers excellent design versatility as it can be made into panels of almost any shape and size as well as being suitable for curved panels, rolling and perforating.

Finished Before Fabrication

Unlike traditional powder coated panels, ULTRASURE is prefinished with factory applied PVDF coating and a protective peel-off film before fabrication into cladding panels providing many practical advantages.

AS 1530.1 Non-Combustible

ULTRASURE is one of the few aluminium cladding panel solutions that is deemed-to-satisfy non-combustible when tested to AS 1530.1 and AS 1530.3 as per the requirements of NCC 2022 Clause C2D10(6)(e).

NCC 2022 Compliance

ULTRASURE solid aluminium panel is deemed-to-satisfy non-combustible as per NCC 2022 Clause C2D10(6)(e) making it compliant for use as external cladding on any project of types A, B & C construction.

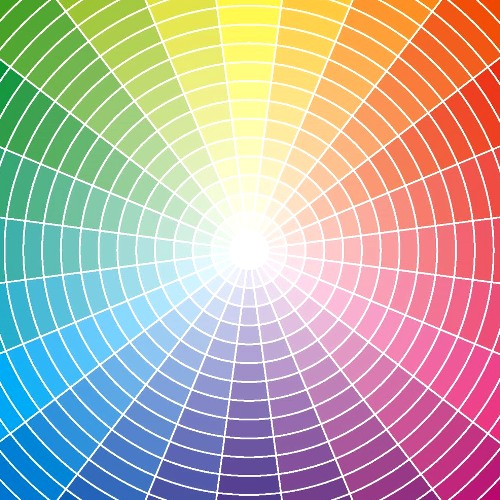

Unlimited Custom Colours

ULTRASURE 3mm solid aluminium panel utilises the same PVDF coating as ULTRABOND FR and ULTRACORE so it is available in the same extensive colour range and custom colours. MOQ’s apply.

PVDF Paint System

ULTRASURE 3mm aluminium panel only uses the highly recognised PVDF KYNAR 500 or FEVE paints known for their high durability, providing the optimum resistance to weather and industrial pollution.

Manufacturer's Warranty

ULTRASURE 3mm aluminium panel coating system has a long track record of consistency, reliability and quality allowing us to offer up to 15 year's warranty when installed by a licensed installer.

Availability

Product Range

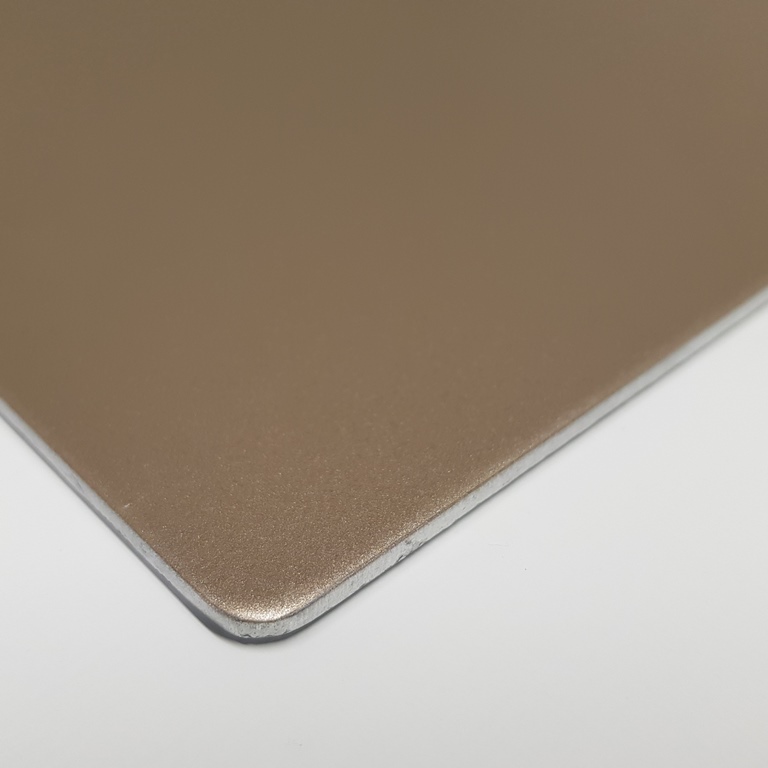

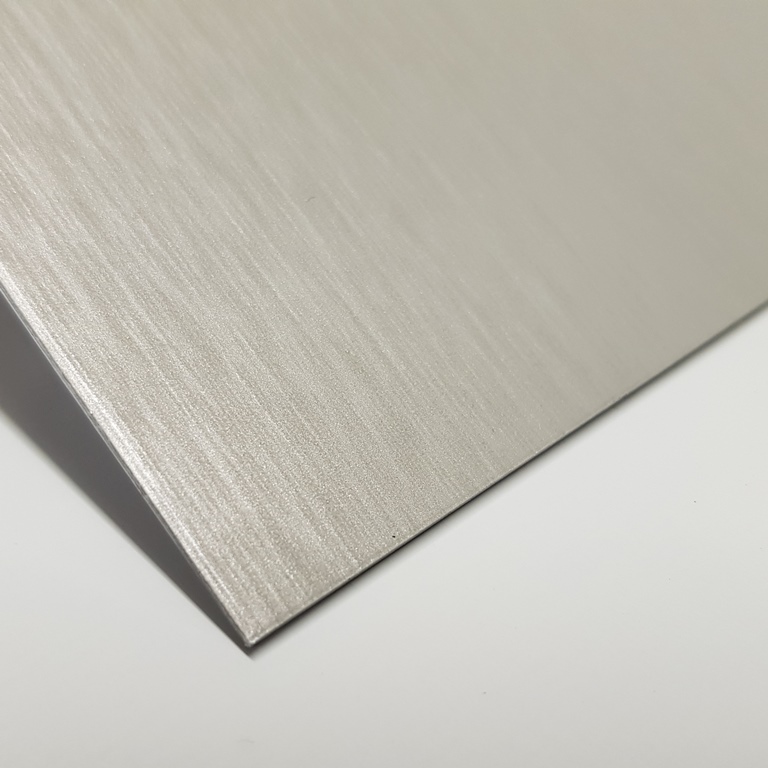

| ULTRASURE Metallic Colours |

ULTRASURE Solid Colours |

ULTRASURE Metal Imitations |

|

|

|

Availability

|

Description |

Sheet Sizes |

Lead Time |

MOQ |

|---|---|---|---|

|

ULTRASURE Metallic Colours |

2500, 3200, 4000 x 1250mm 2500, 3200, 4000 x 1500mm |

10-12 Weeks |

1200m2 |

|

ULTRASURE Solid Colours |

2500, 3200, 4000 x 1500mm 2500, 3200, 4000 x 1500mm |

10-12 Weeks |

1200m2 |

|

ULTRASURE Non-stock, BCG & Custom Colours |

2500, 3200, 4000 x 1250mm 2500, 3200, 4000 x 1500mm |

10-12 Weeks |

1200m2 |

|

ULTRASURE Metal Imitation Finishes |

2500, 3200, 4000 x 1250mm 2500, 3200, 4000 x 1500mm |

10-12 Weeks |

1200m2 |

Please Note: Minimum order is 1200m2 per width (1250mm or 1500mm).

Accessories

| Code |

Description |

Lead Time |

MOQ |

|---|---|---|---|

| CFM30 | EUROFIX 30mm Metal Screw (Colour), 250 Pack | 3-4 Weeks | 1 Pack |

| CFMW30 | EUROFIX 30mm Screw & Washer (Colour), 250 Pack | 3-4 Weeks | 1 Pack |

System Components

| BICEP Facade System |

IROCK AS 1530.1 Insulation |

ULTRAPERM Class 4 Membrane |

STUDTEK Steel Top-hats |

PROLASTIK Joint Sealant |

|

|

|

|

|

Colour Chart

Gallery

Downloads

Support

Customer Support

For same-day design assistance and technical support please contact our sales team directly on the below contact details. All our sales team and technical staff are locally based here in each timezone of Australia (AU) so we can provide the best possible service and support for your projects.

You can also request pricing or project-specific quotations using the below contact details. Please note, each of our email addresses is as per the following format and as set out below:

| Ben Kennard | Daniel Hornsey | Ryan Webb | Jon Wallis |

| NSW & ACT | VIC & TAS | WA & SA | QLD & NT |

| P: 1300 945 123 | P: 1300 945 123 | P: 1300 945 123 | P: 1300 945 123 |

| M: 0400 888 333 | M: 0429 936 164 | M: 0424 755 325 | M: 0437 606 007 |

| Email Handle: ben.k@ | Email Handle: daniel@ | Email Handle: ryan@ | Email Handle: jon@ |

| LinkedIn Profile | LinkedIn Profile | LinkedIn Profile | LinkedIn Profile |

- Overview

- Availability

- Colour Chart

- Gallery

- Downloads

- Support