IROCK

- Overview

- Availability

- Gallery

- Downloads

- Support

Overview

Non-combustible Insulation

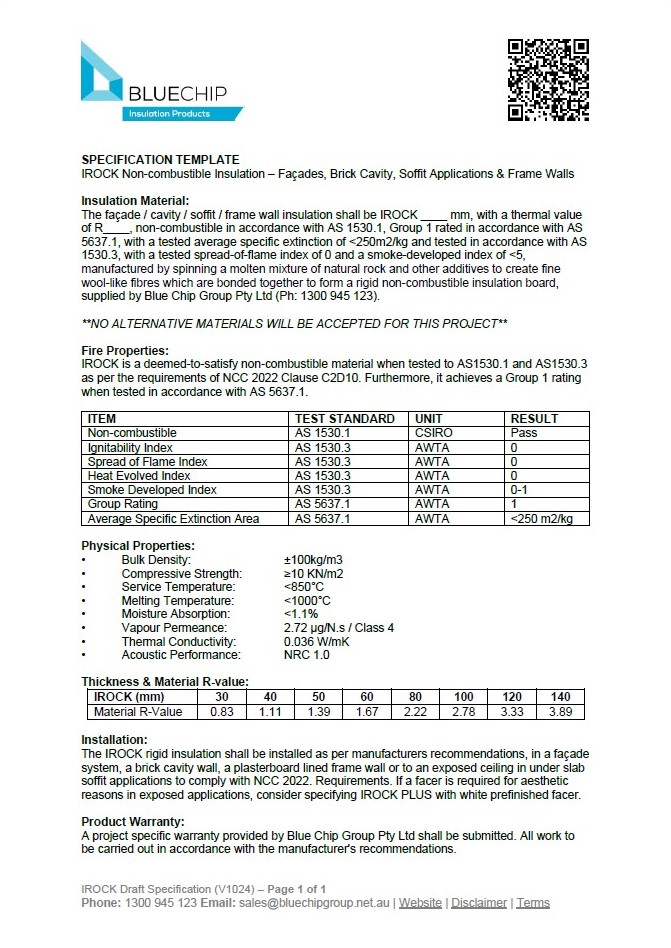

IROCK non-combustible insulation is a thermal and acoustic stonewool insulation material widely used in both external and internal wall applications that require high levels of fire safety and thermal performance. IROCK is manufactured by spinning a molten mixture of natural rock materials and other additives to create fine wool-like fibres which are bonded together using a thermoset resin to form a rigid insulation board. Compliant with all aspects of NCC 2022 fire requirements, IROCK offers excellent long-term ageing performance and superior resistance to water absorption compared to other common insulation materials.

Non-combustible

IROCK is deemed non-combustible when tested to AS 1530.1 meaning it is compliant for use in external walls and cladding systems where insulation is required to be non-combustible for buildings of types A & B construction.

Moisture Resistant

Although it is not suitable for permanent immersion or exposure to drenching, IROCK insulation board's thermal performance will not be adversely affected by condensation or contact with liquid water.

Excellent Acoustic Performance

Along with excellent fire safety and thermal performance, IROCK also provides an excellent acoustic performance of NRC >1.0 in accordance with ISO 354-2006 providing an ideal solution for party walls.

Light-weight & Ultra-durable

IROCK non-combustible insulation boards are both very lightweight and highly durable for safe hassle-free handling onsite and they can be easily cut and formed to suit almost any application.

Cost-Effective

With a nominal thermal conductivity of 0.036 W/mK and a very economical price-point, IROCK offers excellent thermal efficiency for minimal upfront cost along with life-cycle energy savings for the building.

Environmentally Friendly

Largely manufactured from recycled materials and natural rock, IROCK is environmentally friendly as an initial product. It also offers numerous environmental benefits in application as thermal insulation.

NCC 2022 Compliant

NCC 2022 Clause C2D10 specifically requires all components of external walls including cladding, insulation and framing to be non-combustible and IROCK is one of only a few materials that meet this criteria.

Superior Ageing Performance

Unlike low density batts which tend to slump in vertical applications or PIR and phenolic insulation which lose thermal performance over time, IROCK is anti-slump and has excellent long-term ageing performance.

Availability

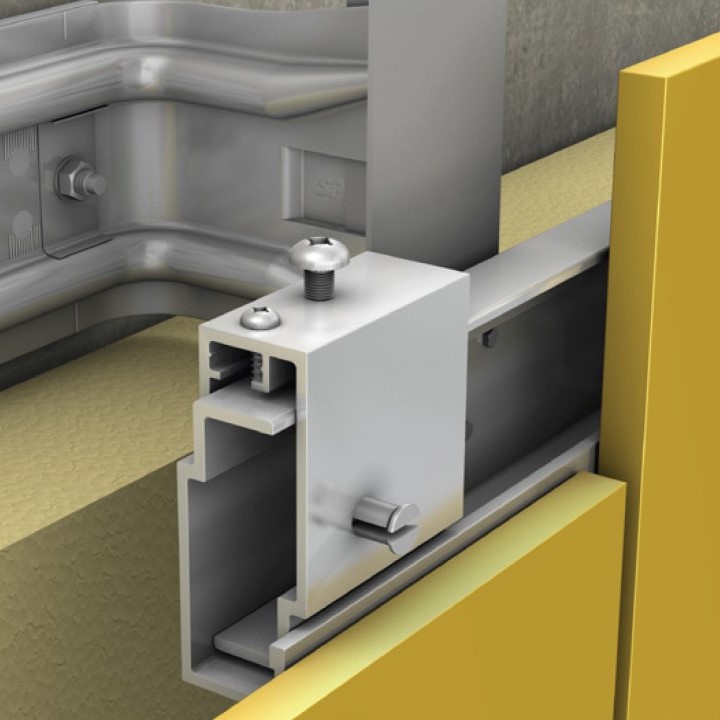

Product Range with Bicep Facade System

| IROCK AS 1530.1 Insulation |

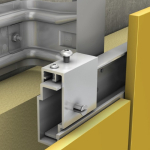

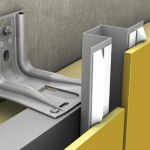

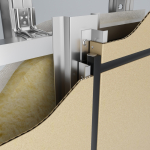

IROCK + BICEP Horizontal System |

IROCK + BICEP Vertical System |

IROCK + BICEP Visible-fix System |

IROCK + BICEP Concealed-fix System |

|

|

|

|

|

Irock Availability

| Code | R-value |

Description |

Lead Time |

MOQ |

|---|---|---|---|---|

| IR301206 | R0.83 | IROCK 30mm Stonewool Insulation, 1200 x 600mm | 8-10 Weeks | 2,160m2 |

| IR401206 | R1.11 | IROCK 40mm Stonewool Insulation, 1200 x 600mm | Stock | 8 Boards |

| IR501206 | R1.39 | IROCK 50mm Stonewool Insulation, 1200 x 600mm | 8-10 Weeks | 1,368m2 |

| IR601206 | R1.67 | IROCK 60mm Stonewool Insulation, 1200 x 600mm | Stock | 5 Boards |

| IR801206 | R2.22 | IROCK 80mm Stonewool Insulation, 1200 x 600mm | Stock | 4 Boards |

| IR1001206 | R2.78 | IROCK 100mm Stonewool Insulation, 1200 x 600mm | Stock | 8 Boards |

| IR1201206 | R3.33 | IROCK 120mm Stonewool Insulation, 1200 x 600mm | Stock | 5 Boards |

Irock Technical Data

| Test Item |

Standard |

Result |

|---|---|---|

| Thermal Conductivity | ASTM C518 | 0.036 W/mK |

| Acoustic Performance | ISO 354-2006 | 1.0 NRC |

| Non-combustible | AS 1530.1 | Pass* |

| Group Fire Rating | AS 5637.1 | 1** |

| Average Specific Extinction | AS 5637.1 | <250 m2/kg** |

| Spread of Flame Index | AS 1530.3 | 0*** |

| Smoke Developed Index | AS 1530.3 | 0-1*** |

| Material Density | Actual | 100 kg/m3 |

| Maximum Service Temperature | Actual | >850°C |

| Melting Temperature | Actual | >1000°C |

| Water Absorption | EN 1609 | <1.1% |

| Vapour Permeability | ASTM E96 | Class 4 |

*IROCK, when tested to AS 1530.1, is deemed non-combustible meaning it can be used in all external walls and facade applications. **IROCK, when tested as per AS 5637.1, achieves a Group 1 rating and an average specific extinction of <250 m2/kg meaning it can be used in all internal wall and lining applications. ***IROCK, when tested to AS 1530.3, achieves a spread-of-flame index of 0 and a smoke-developed index <5 meaning it can be used in all other insulation applications.

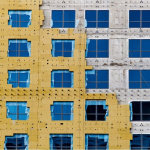

Gallery

Downloads

Support

Customer Support

For same-day design assistance and technical support please contact our sales team directly on the below contact details. All our sales team and technical staff are locally based here in each timezone of Australia (AU) so we can provide the best possible service and support for your projects.

You can also request pricing or project-specific quotations using the below contact details. Please note, each of our email addresses is as per the following format and as set out below:

| Ben Kennard | Daniel Hornsey | James Alexander | Jon Wallis |

| NSW & ACT | VIC & TAS | WA & SA | QLD & NT |

| P: 1300 945 123 | P: 1300 945 123 | P: 1300 945 123 | P: 1300 945 123 |

| M: 0400 888 333 | M: 0429 936 164 | M: 0477 966 028 | M: 0437 606 007 |

| Email Handle: ben.k@ | Email Handle: daniel@ | Email Handle: james@ | Email Handle: jon@ |

| LinkedIn Profile | LinkedIn Profile | LinkedIn Profile | LinkedIn Profile |

- Overview

- Availability

- Gallery

- Downloads

- Support