EXERAMIC

- Overview

- Availability

- Colour Chart

- Gallery

- Downloads

- Support

Overview

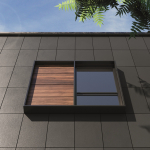

Ceramic Tile Facade System

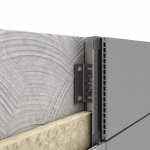

The EXERAMIC facade system comprises a high-tech extruded ceramic tile installed using the proprietary BICEP bracketry system. The EXERAMIC facade system can also be installed as an insulated system using our IROCK non-combustible insulation for high-end projects, decreasing energy costs and CO2 emissions at the same time. The EXERAMIC facade system offers extreme performance against the elements and is fast to install, economical and environmentally friendly. Available in a wide variety of natural finishes including terracotta, stone, cement, marble and timber finishes, EXERAMIC is an exceptional façade solution.

Extreme Durability

EXERAMIC ceramic facade tiles are tested to ISO 10545-4 and they easily achieve double the standard breaking strength of ≥ 3.000 N. In fact, EXERAMIC ceramic facade tiles are able to withstand a huge ≥ 6.000 N.

Precision Manufacturing

Manufactured according to ISO 10545-2, the high-precision extrusion technology used for EXERAMIC ceramic facade tiles means they are rectified on all 4 sides, reducing tolerances to a minimum and ensuring precision installation.

Non-Combustible

As expected, EXERAMIC ceramic facade tiles are a deemed-to-satisfy non-combustible facade material in accordance with NCC 2022 clause C2D10(5)(i) meaning they can be used internally or externally wherever a non-combustible material is required.

EPD Verified for Performance

EXERAMIC ceramic facade tiles are eco-sustainable and are a 100% recyclable building material. EXERAMIC ceramic facade tiles have been EPD verified to enable use in the most environmentally sensitive construction projects.

Eco-Friendly Circular Economy

Heavily focused on the circular economy, the EXERAMIC manufacturing process recovers 100% of the residual material generated during the production process, reintroducing approximately 40% of recycled content into the raw material.

Naturally Forever

Enriching new and refurbished buildings, EXERAMIC ceramic facade tiles impart an exclusive contemporary character to all projects. They are elegant, natural and look virtually unchanged over an independently declared service life of 50+ years.

Technical Support

Advanced project support is available to assist with engineering and full facade details for the EXERAMIC system from basic ventilated systems to complete insulated and ventilated facades. Please get in touch to discuss your project in further detail.

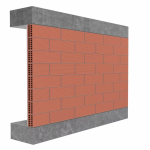

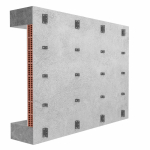

Ventilated & Insulated System

EXERAMIC ceramic facade tiles are installed on the BICEP bracketry system allowing for a ventilated and/or insulated system with varying cavity depths for different insulation thicknesses. Improve your project's thermal and energy efficiency by R3.33+.

Availability

Product Range

|

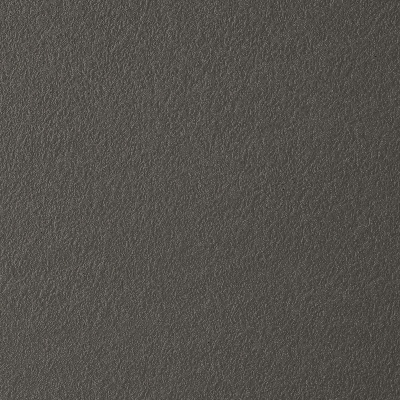

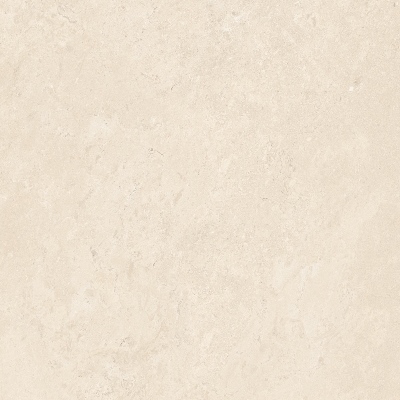

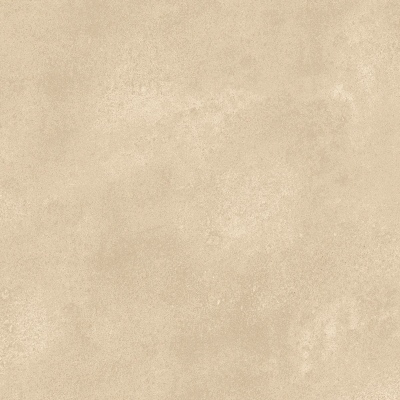

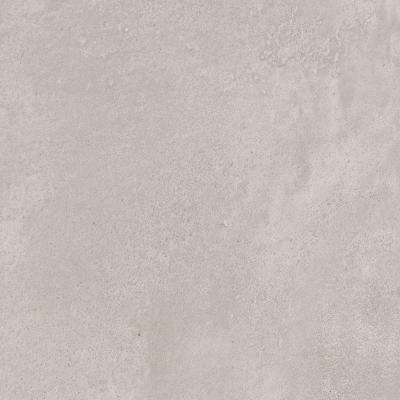

EXERAMIC Terracotta Finish |

EXERAMIC Stone Finish |

EXERAMIC Cement Finish |

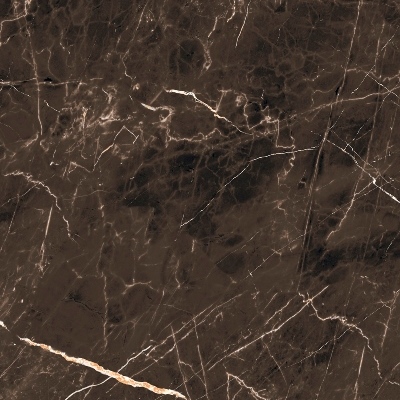

EXERAMIC Marble Finish |

EXERAMIC Timber Finish |

|

|

|

|

|

Profiles

|

Specification Code: EXERAMIC 397 x 20mm Tile Profile |

|

| Specification Code: EXERAMIC 600 x 20mm Tile Profile |

Availability

|

Description |

Tile Sizes |

Lead Time |

MOQ |

|---|---|---|---|

|

EXERAMIC 397 x 20mm Tile Profile |

800, 1000, 1200, 1600mm Lengths |

14-16 Weeks |

300m2 |

|

EXERAMIC 600 x 20mm Tile Profile |

800, 1000, 1200, 1600mm Lengths |

14-16 Weeks |

300m2 |

Accessories

| ETSCS Starter Clip Single |

ETSCD Starter Clip Double |

ETJCS Joint Clip Single |

ETJCD Joint Clip Double |

|

|

|

|

| Code |

Description |

Lead Time |

MOQ |

|---|---|---|---|

| ETSCS | EXERAMIC Stainless Starter Clip Single, 250 Pack | 3-4 Weeks | 1 Pack |

| ETSCD | EXERAMIC Stainless Starter Clip Double, 250 Pack | 3-4 Weeks | 1 Pack |

| ETJCS | EXERAMIC Stainless Joint Clip Single, 250 Pack | 3-4 Weeks | 1 Pack |

| ETJCD | EXERAMIC Stainless Joint Clip Double, 250 Pack | 3-4 Weeks | 1 Pack |

System Components

| BICEP Facade System |

IROCK AS 1530.1 Insulation |

ULTRAPERM Class 4 Membrane |

STUDTEK Steel Top-hats |

PROLASTIK Joint Sealant |

|

|

|

|

|

Colour Chart

Gallery

Downloads

Support

Customer Support

For same-day design assistance and technical support please contact our sales team directly on the below contact details. All our sales team and technical staff are locally based here in each timezone of Australia (AU) so we can provide the best possible service and support for your projects.

You can also request pricing or project-specific quotations using the below contact details. Please note, each of our email addresses is as per the following format and as set out below:

| Ben Kennard | Daniel Hornsey | James Alexander | Jon Wallis |

| NSW & ACT | VIC & TAS | WA & SA | QLD & NT |

| P: 1300 945 123 | P: 1300 945 123 | P: 1300 945 123 | P: 1300 945 123 |

| M: 0400 888 333 | M: 0429 936 164 | M: 0477 966 028 | M: 0437 606 007 |

| Email Handle: ben.k@ | Email Handle: daniel@ | Email Handle: james@ | Email Handle: jon@ |

| LinkedIn Profile | LinkedIn Profile | LinkedIn Profile | LinkedIn Profile |

- Overview

- Availability

- Colour Chart

- Gallery

- Downloads

- Support